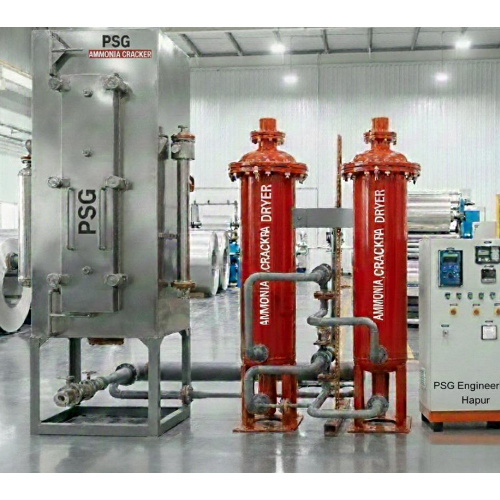

Cracked Ammonia Generator For Bright Annealing Of Stainless Steel

Cracked Ammonia Generator For Bright Annealing Of Stainless Steel Specification

- Type

- Cracked Ammonia Generator

- Material

- Stainless Steel

- Production Capacity

- 25 Nm3/hr

- Production Rate

- Continuous

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Controlled

- Purity(%)

- 99.99%

- Voltage

- 380-440 V

- Power

- 15 kW

- Working Pressure

- 2-4 kg/cm

- Weight (kg)

- 1100 kg

- Dimension (L*W*H)

- 2600 x 1000 x 1600 mm

- Color

- Metallic Grey

- Cooling Method

- Water Cooled

- Service

- On-site installation and commissioning

- Start-up Time

- 30 minutes

- Gas Dew Point

- -70°C

- Output Gas Composition

- Hydrogen: 75%, Nitrogen: 25%

- Mobility

- Stationary, Skid Mounted

- Ammonia Cracking Temperature

- 800°C

- Safety Feature

- Integrated auto shut-off

- Application

- Bright Annealing of Stainless Steel

- Feedstock

- Liquid Ammonia

Cracked Ammonia Generator For Bright Annealing Of Stainless Steel Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 15 Days

About Cracked Ammonia Generator For Bright Annealing Of Stainless Steel

Directions and Suitable Use for Cracked Ammonia Generator

This generator is tailored for the continuous bright annealing process in stainless steel manufacturing facilities. For optimal results, deploy the system in areas where stationary, skid-mounted configurations are suitable. The automated controls and quick start-up enable easy operation-simply feed liquid ammonia and let the PLC-controlled unit handle the rest. Its robust stainless steel build ensures longevity, while water-cooling maintains operational safety during extended use.

Sample Policy, Availability, and Delivery Terms

We supply samples of our Cracked Ammonia Generator upon proposal approval and confirmation of a nominal amount. Samples are available for review, allowing our clients to experience the device's performance firsthand before formal purchase is handed over. Shipments are managed from our designated FOB port in India, ensuring transparent and streamlined logistics. Our attentive service team is ready to guide you through each stage from sample provision to installation.

FAQ's of Cracked Ammonia Generator For Bright Annealing Of Stainless Steel:

Q: How does the Cracked Ammonia Generator facilitate the bright annealing process?

A: The generator produces a protective atmosphere of hydrogen and nitrogen by cracking liquid ammonia, which helps prevent oxidation and ensures a bright, clean finish on stainless steel during annealing.Q: What safety features are included in this ammonia generator?

A: It comes with an integrated auto shut-off safety feature, water-cooled system, and PLC control to ensure safe, uninterrupted operation with minimal manual intervention.Q: When is the best time to use this generator in a stainless steel production line?

A: The generator is ideal for continuous operation during the bright annealing phase, providing a steady supply of high purity gas at a rapid start-up time of 30 minutes.Q: What is the output gas purity and why is it beneficial?

A: The output gas has a purity of 99.99%, ensuring optimal results in bright annealing by minimizing oxidation and enhancing the surface quality of stainless steel products.Q: Where can customers see or test a sample unit before purchase?

A: Sample units are available upon request and proposal confirmation. We invite interested buyers to review or test the generator at their facilities or at designated demonstration sites before proceeding with a full purchase.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ammonia Cracker Plant Category

Hydrogen Generation From Ammonia Cracker

Price 650000 INR / Unit

Minimum Order Quantity : 1 Unit

Working Pressure : 520 kg/cm2

Color : Other, Silver Grey

Power : 10 kW

Control System : Other, PLC Controlled

Ammonia Cracker Unit

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Working Pressure : 0.5 kg/cm to 1.5 kg/cm

Color : Other, Blue / Customized

Power : 6 kW to 25 kW (Depending on model)

Control System : Other, PLC Based Control Panel

Ammonia Cracker Hydrogen Generator For Carbon Steel Decarburization

Price 950000 INR / Unit

Minimum Order Quantity : 1 Unit

Working Pressure : 1.01.5 kg/cm2

Color : Other, Gray

Power : 15 kW

Control System : Other, PLC Based

Ammonia Cracking Hydrogen Plant For Sintering & Galvanizing

Price 1150000 INR / Unit

Minimum Order Quantity : 1 Unit

Working Pressure : 0.51.0 kg/cm2

Color : Other, Silver/Grey

Power : 7.5 kW

Control System : Other, PLC Based