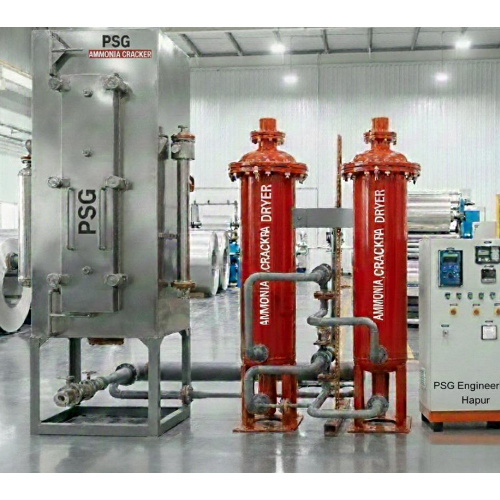

Ammonia Cracker Hydrogen Generator For Carbon Steel Decarburization

Ammonia Cracker Hydrogen Generator For Carbon Steel Decarburization Specification

- Type

- Ammonia Cracker Hydrogen Generator

- Material

- Carbon Steel

- Production Capacity

- 50 Nm3/hr

- Production Rate

- Variable as per requirement

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Based

- Purity(%)

- 99.99%

- Voltage

- 415 V

- Power

- 15 kW

- Working Pressure

- 1.0-1.5 kg/cm2

- Weight (kg)

- 1800 kg

- Dimension (L*W*H)

- 3500 mm x 1500 mm x 2200 mm

- Color

- Gray

- Ambient Operating Temperature

- 5°C to 45°C

- Application

- Carbon Steel Decarburization, Metal Treatment

- Cooling System

- Water Cooled

- Outlet Gas Temperature

- 800°C

- Installation Method

- Skid Mounted

- Purifier Type

- Catalytic Purifier

- Service Life

- Over 10 Years

- Feedstock

- Liquid Ammonia

- Gas Outlet Connection

- Flanged

- Safety Features

- Overheat Protection, Ammonia Leak Detector

- Heating Element Type

- Nickel-Chromium Alloy

Ammonia Cracker Hydrogen Generator For Carbon Steel Decarburization Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 15 Days

About Ammonia Cracker Hydrogen Generator For Carbon Steel Decarburization

Versatile Application & Competitive Benefits

The Ammonia Cracker Hydrogen Generator excels at carbon steel decarburization, metal treatment, and similar industrial uses. Its variable production rate and robust construction make it ideal for general and specific tasks in steel plants and manufacturing units. Primary advantages include its long service life, reliable safety protocols, and adaptable operation. This generator truly stands out for high output, purity, and trusted results where hydrogen gas generation is vital for processing excellence.

Payment, Certification & Export Details

For domestic and international markets, we offer favorable payment terms to suit your procurement needs. Pricing is competitive, with clear asking price and prompt Purchase Order processing. Certified for quality standards, this product is ready for deployment worldwide. Our main export markets span across India and global regions, assuring clients of compliance and professional support for seamless transactions and prompt product delivery.

FAQ's of Ammonia Cracker Hydrogen Generator For Carbon Steel Decarburization:

Q: How does the ammonia cracker hydrogen generator contribute to carbon steel decarburization?

A: The generator provides high-purity hydrogen gas, which facilitates the removal of carbon from steel during the decarburization process, improving the quality and characteristics of the finished metal.Q: What are the main safety features included in this generator?

A: This system incorporates overheat protection and an ammonia leak detector, ensuring a secure operational environment and minimizing risks to personnel and equipment.Q: Where can the generator be installed and operated effectively?

A: The hydrogen generator is skid mounted for easy placement and is designed to operate in ambient temperatures ranging from 5C to 45C, making it suitable for various manufacturing or processing sites.Q: What is the typical service life and maintenance outlook for this product?

A: With a service life exceeding 10 years, the generator requires minimal routine maintenance, thanks to its robust build and reliable components.Q: How is hydrogen gas output regulated to match specific requirements?

A: The production rate of hydrogen gas is variable and can be adjusted as per operational needs, ensuring flexibility for diverse industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ammonia Cracker Plant Category

Cracked Ammonia Gas Generator

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Purity(%) : 99.99

Computerized : No

Material : Mild Steel

Type : Other, Cracked Ammonia Gas Generator

Cracked Ammonia Generator For Bright Annealing Of Stainless Steel

Price 1050000 INR / Unit

Minimum Order Quantity : 1 Unit

Purity(%) : 99.99%

Computerized : Yes

Material : Stainless Steel

Type : Other, Cracked Ammonia Generator

Ammonia Cracker Unit

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Purity(%) : 75% Hydrogen, 25% Nitrogen (v/v)

Computerized : Yes

Material : Mild Steel with Nickel Catalyst

Type : Other, Ammonia Cracker Unit

Industrial Ammonia Cracker Plant

Price 577000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Purity(%) : Dew Point 40 to 60 deg c

Computerized : No

Material : Mild Steel

Type : Other