Hydrogen Generation from Ammonia Cracker

Hydrogen Generation from Ammonia Cracker Specification

- Type

- Hydrogen Generation from Ammonia Cracker

- Material

- Stainless Steel

- Production Capacity

- 5 Nm3/hr to 1000 Nm3/hr

- Production Rate

- As per requirement

- Computerized

- Yes

- Automatic Grade

- Fully Automatic

- Control System

- PLC Based

- Purity(%)

- 99.99%

- Voltage

- 380 V

- Power

- 7.5 kW 120 kW

- Working Pressure

- 0.5 kg/cm2 to 2.5 kg/cm2

- Weight (kg)

- As per model

- Dimension (L*W*H)

- As per model selection

- Color

- Silver

- Dew Point

- -60°C

- Mounting Type

- Skid Mounted

- Feedstock

- Anhydrous Ammonia (NH3)

- Cooling Type

- Water cooled/air cooled

- Service Support

- Available

- Start-up Time

- 60-90 minutes

- Application

- Hydrogen supply for Industrial/Metallurgical use

- Outlet Gas Composition

- 75% H2, 25% N2 (approx.)

- Catalyst Type

- Nickel-based catalyst

- Safety Features

- Flame arrestor, Ammonia detector, Over-pressure protection

- Operation Temperature

- 800°C to 900°C

Hydrogen Generation from Ammonia Cracker Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 15 Days

About Hydrogen Generation from Ammonia Cracker

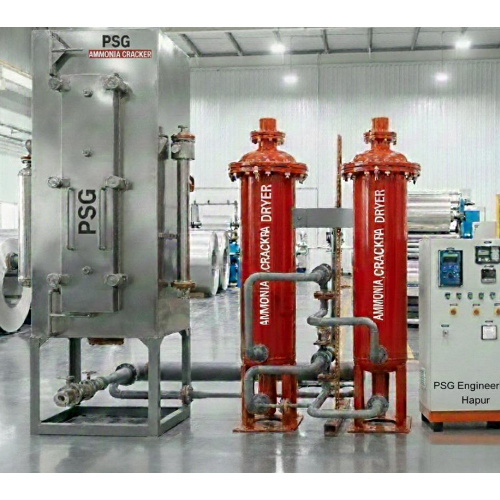

Presenting our dazzling Hydrogen Generation from Ammonia Cracker unit, engineered for monumental performance and popular among industry leaders. Powered by fresh, anhydrous ammonia (NH3) as the feedstock, this exquisite system operates at 800C-900C to ensure remarkable purity (99.99%) and efficiency. With instant checkout and swift start-up times (60-90 minutes), our nickel-based catalyst delivers outlet gas composition of 75% H2 and 25% N2. Enhanced safety features like flame arrestor, ammonia detector, and over-pressure protection, combined with fully automatic PLC controls, guarantee reliability. Skid-mounted and made from robust stainless steel, it serves industrial and metallurgical applications effortlessly. Service support and customizable output from 5 Nm3/hr to 1000 Nm3/hr ensure it's the ideal choice for hydrogen supply.

Competitive Edge & Plant Usage

Harness competitive advantages with our Hydrogen Generation from Ammonia Cracker-designed for instant hydrogen supply in industrial and metallurgical applications. This plant excels through efficient conversion using computerized, PLC-based automation and nickel-based catalysts. Application methods include plug-and-play skid-mounted installation for fresh deployment, optimizing hydrogen output with dazzling speed. Vast operating ranges and robust safety make this unit highly suitable for monumental projects needing continuous, high-purity hydrogen.

Certifications, Shipping, & Supply Capability

Our Hydrogen Generation from Ammonia Cracker comes certified to meet industry standards, ensuring reliability for each shipment. Supplied from India, manufacturers guarantee a steady supply with a production capacity tailored to sale price and project requirements. Secure FOB port operations ensure rapid cargo movement, while our supply ability ensures both single and bulk shipments can be processed instantly. Extensive support and guaranteed availability accompany every unit, making procurement efficient and hassle-free.

Competitive Edge & Plant Usage

Harness competitive advantages with our Hydrogen Generation from Ammonia Cracker-designed for instant hydrogen supply in industrial and metallurgical applications. This plant excels through efficient conversion using computerized, PLC-based automation and nickel-based catalysts. Application methods include plug-and-play skid-mounted installation for fresh deployment, optimizing hydrogen output with dazzling speed. Vast operating ranges and robust safety make this unit highly suitable for monumental projects needing continuous, high-purity hydrogen.

Certifications, Shipping, & Supply Capability

Our Hydrogen Generation from Ammonia Cracker comes certified to meet industry standards, ensuring reliability for each shipment. Supplied from India, manufacturers guarantee a steady supply with a production capacity tailored to sale price and project requirements. Secure FOB port operations ensure rapid cargo movement, while our supply ability ensures both single and bulk shipments can be processed instantly. Extensive support and guaranteed availability accompany every unit, making procurement efficient and hassle-free.

FAQ's of Hydrogen Generation from Ammonia Cracker:

Q: How does the Hydrogen Generation from Ammonia Cracker operate?

A: The system utilizes anhydrous ammonia as feedstock, which is cracked at high temperatures (800C-900C) using a nickel-based catalyst. This process produces a gas mixture of 75% hydrogen and 25% nitrogen, with high purity suitable for industrial applications.Q: What safety features are included in this hydrogen generation unit?

A: Our unit is equipped with a flame arrestor, ammonia detector, and over-pressure protection to ensure safe operation during hydrogen generation. These features provide robust safety for operators and the surrounding environment.Q: When can the plant begin producing hydrogen after start-up?

A: The system features a swift start-up time of 60 to 90 minutes. After start-up, the plant can immediately begin producing high-purity hydrogen suitable for your industrial needs.Q: Where is the Hydrogen Generation from Ammonia Cracker supplied from?

A: This system is manufactured and supplied from India. We support global shipments and can cater to various project locations worldwide through trusted FOB port operations.Q: What is the benefit of using computerized PLC-based control?

A: A PLC-based control system ensures fully automatic operation, consistent output, precise monitoring, and quick adjustment of processes, resulting in optimized hydrogen generation and increased operational efficiency.Q: How can I choose the right production capacity for my application?

A: Our ammonia cracker units offer customizable production rates from 5 Nm3/hr to 1000 Nm3/hr, allowing you to select a model that matches your hydrogen usage and specific project requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ammonia Cracker Plant Category

Ammonia Cracker Unit

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 415 V

Computerized : Yes

Material : Mild Steel with Nickel Catalyst

Automatic Grade : Automatic

Cracked Ammonia Generator For Bright Annealing Of Stainless Steel

Price 1050000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380440 V

Computerized : Yes

Material : Stainless Steel

Automatic Grade : Automatic

Ammonia Cracking Furnace

Price 550000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 415 V

Computerized : No

Material : Mild Steel

Automatic Grade : SemiAutomatic

Industrial Ammonia Cracker Plant

Price 577000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 480 Volt (v)

Computerized : No

Material : Mild Steel

Automatic Grade : SemiAutomatic