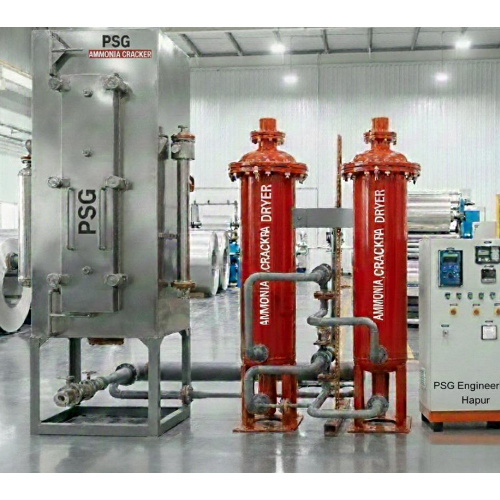

Cracked Ammonia Hydrogen Gas Generation Unit

Cracked Ammonia Hydrogen Gas Generation Unit Specification

- Type

- Cracked Ammonia Hydrogen Gas Generation Unit

- Material

- Mild Steel

- Production Capacity

- 500 Nm3/hr to 3000 Nm3/hr

- Production Rate

- Continuous

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Purity(%)

- 99.99%

- Voltage

- 415 V

- Power

- 20 kW

- Working Pressure

- 3 - 10 kg/cm

- Weight (kg)

- 2000 kg

- Dimension (L*W*H)

- 3500 mm x 1800 mm x 2200 mm

- Color

- Blue and Silver

- Feedstock Specification

- Anhydrous ammonia

- Fuel Requirement

- No external fuel required uses ammonia feed

- Catalyst

- Nickel based

- Outlet Connection

- Standard flanged outlet

- Cooling System

- Integrated water cooling

- Maintenance

- Low, with easy access to components

- Operating Temperature

- 800C to 900C

- Start Up Time

- Approx. 60 minutes

- Gas Output

- Hydrogen and Nitrogen Mixture

- Application

- Suitable for metallurgical, electrical, and heat treatment industries

- Capacity Adjustment

- Manual or automatic depending on model

- Ammonia Flow Rate

- Adjustable via flow control system

- Environmental Compliance

- Meets emission and safety regulations

- Installation

- Skid mounted for easy installation

- Safety Features

- Pressure safety valve, gas leak detectors

Cracked Ammonia Hydrogen Gas Generation Unit Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 15 Days

About Cracked Ammonia Hydrogen Gas Generation Unit

Applications and Surface Suitability

The Cracked Ammonia Hydrogen Gas Generation Unit is extensively used in metallurgical, electrical, and heat treatment industries. Its surface of application ranges from steel fabrication plants to high-temperature processing units and laboratory environments. With its adaptable feedstock specification and high purity output, it is also suitable for use in processes demanding precise hydrogen-nitrogen mixtures, ensuring consistent results and reliability wherever advanced gas generation is required.

Payment, Export Markets, and Certifications

Enjoy competitive freight terms and the lowest price offers with instant checkout options for our Cracked Ammonia Hydrogen Gas Generation Unit. We cater to major export markets across Asia, Europe, and the Middle East, delivering certified quality under rigorous environmental and safety standards. Customers benefit from seamless payment terms and documentation for international import, making procurement simple and reliable for global buyers.

FAQ's of Cracked Ammonia Hydrogen Gas Generation Unit:

Q: How does the Cracked Ammonia Hydrogen Gas Generation Unit operate?

A: The unit transforms anhydrous ammonia into a hydrogen and nitrogen gas mixture by passing it over a nickel-based catalyst at 800C-900C. The process is controlled via a PLC system for optimal output and safety.Q: What are the main benefits of using a cracked ammonia generator in industrial applications?

A: It offers continuous production with high purity (99.99%), low maintenance requirements, and integrated safety features, ensuring efficiency, reliability, and compliance with environmental regulations-all using ammonia as a feedstock, with no external fuel needed.Q: When is this unit suitable for installation?

A: The Cracked Ammonia Hydrogen Gas Generation Unit is ideal for installation in metallurgical, electrical, and heat treatment facilities where a reliable hydrogen-nitrogen mix is required for continuous processes.Q: Where can buyers source this generator in India?

A: Manufacturers and suppliers offer the unit across India, focusing on major industrial regions, with export options available for international orders.Q: What payment terms and export support are available?

A: Customers benefit from tailored payment terms, detailed freight options, and comprehensive export documentation. Certifications assure compliance with global standards, making cross-border transactions straightforward.Q: How is maintenance handled for the gas generator unit?

A: Maintenance is minimal and facilitated by easy access to components. Regular checks of the pressure safety valve and gas leak detectors support continued safe operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ammonia Cracker Plant Category

Cracked Ammonia Generator For Bright Annealing Of Stainless Steel

Price 1050000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Cracked Ammonia Generator

Computerized : Yes

Material : Stainless Steel

Purity(%) : 99.99%

Hydrogen Generation from Ammonia Cracker

Price 850000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Hydrogen Generation from Ammonia Cracker

Computerized : Yes

Material : Stainless Steel

Purity(%) : 99.99%

Cracked Ammonia Gas Generator

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Cracked Ammonia Gas Generator

Computerized : No

Material : Mild Steel

Purity(%) : 99.99

Ammonia Cracker Hydrogen Generator For Carbon Steel Decarburization

Price 950000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Ammonia Cracker Hydrogen Generator

Computerized : No

Material : Carbon Steel

Purity(%) : 99.99%